Downhole Packing Element

Downhole Completion Tools Accessories and Redress kits Maxrub® is working with equipment suppliers all over the world in oil tool components design and manufacturing. We are not only supplying high quality, precision-engineered products to oil and gas customers, but also actively involved in the design process to improve performance and cost effectiveness of our products. Maxrub® is experienced with new tool development, product optimization, CNC coding and machining services, elastomeric/non-elastomeric seals design and manufacturing.

We are committed to provide robust and reliable solutions for challenging downhole environments such as HPHT and gas applications. Wide variety of packing element materials are available based on the wellbore environment.

The pressure rating of packing elements is determined by the materials selections, design of anti-extrusion system, downhole environment, chemical compatibility, etc. Customer field feedbacks suggest that our downhole packing elements perform well at following working conditions:

● Pressure rating up to 10,100 psi (70 MPa) at 410 F (210 °C)

● Pressure rating up to 15,220 psi (105 MPa) at 352 F (178 °C)

● 10,152psi (70 MPa) at 200F (90 °C) V0 tested by customer (Zero bubble with gas as testing medium).

Maxrub® formulates our rubber compounds based on customized applications upon request. Our packing elements have been used in fracking, cased-hole, open-hole completion, ESP completions, etc.

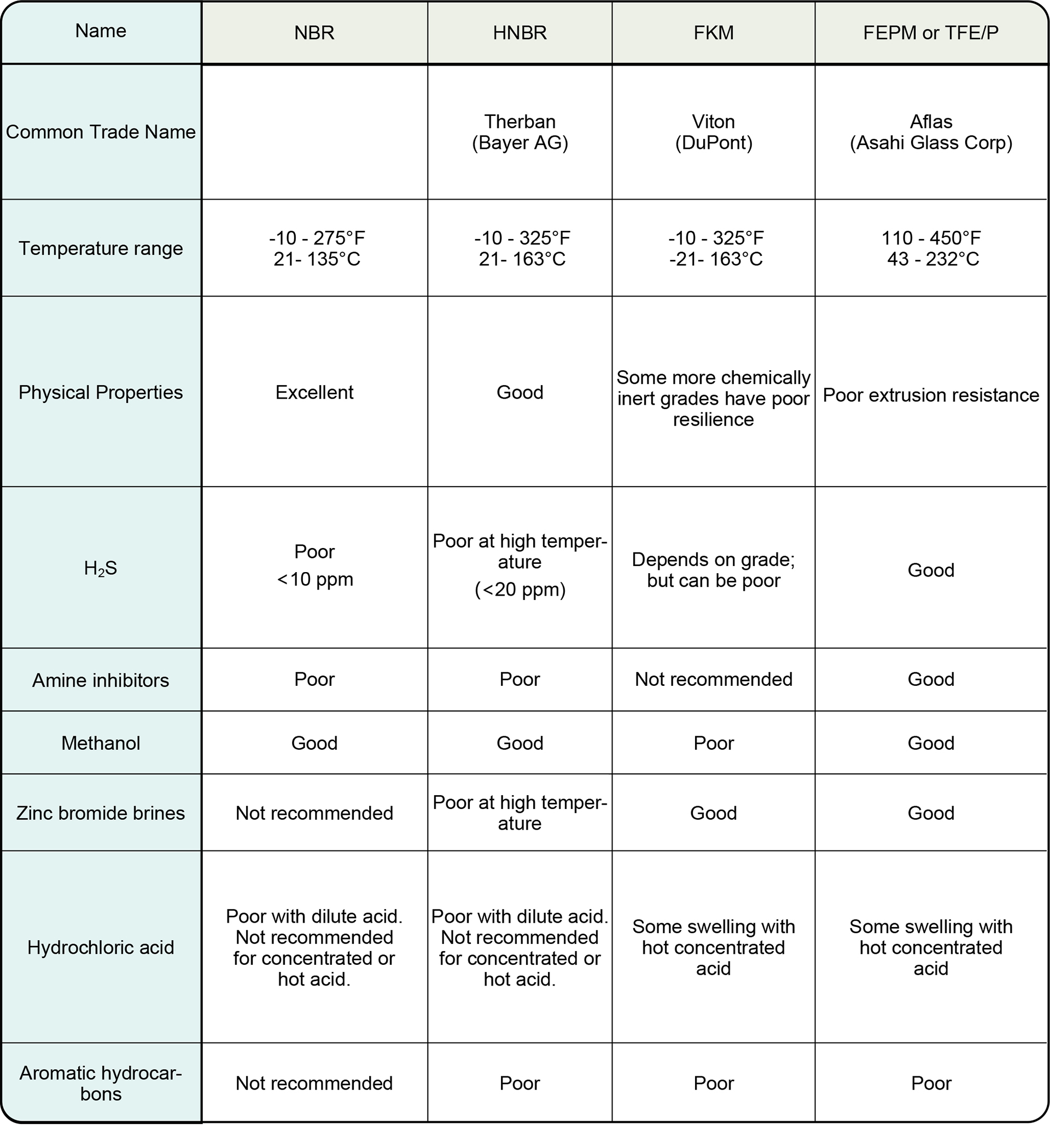

Common packing elements and general material properties are listed as below table for your reference. Please contact us for more detail recommendations.